You would not necessarily think that a marketing email could change the fate of product development, but it does happen from time to time at Schaffner.

The Challenge

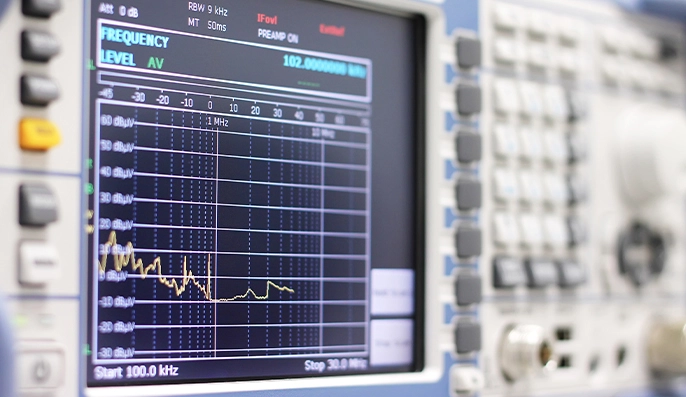

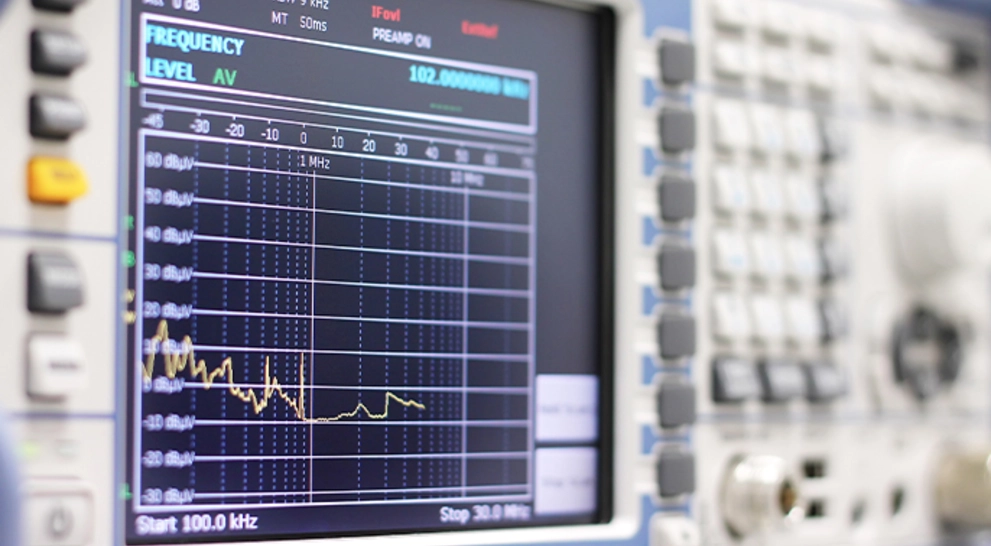

Recently an engineer had a new food inspection system going through the EMC lab. The design failed the conducted emissions test at two frequencies – 5 MHz and 198 KHz.

Perfect Timing

The lab had some sample filters on hand. A few were tried, but they could not knock down both frequencies. The unit under test had some system-level maximum leakage current specifications which required the use of a filter with less capacitance to ground.

Stuck on the problem, the engineer coincidently received a marketing email from Schaffner that day and decided to call for help.

To the Rescue

Schaffner’s Dave Armitage and Tom Larkin quickly got on a call to discuss the testing issues and suggested some other filters that might do the trick. The specific ones (variations of FN2030A and FN2090A) were out of Schaffner’s stock at the moment, but since there was an immediate need, they special-ordered them to be delivered directly to the customer.

Compliance at last!

The filters arrived early the next day and were placed in the locations recommended by Schaffner. Testing of this new configuration allowed the project to pass conducted emissions while also complying with required leakage current limitations.

It just goes to show that it only takes a few small components to make red lights turn green. If you have problems in the EMC testing lab, don’t hesitate to contact your friends at Schaffner.

MORE POWER TO YOU.