Product Overview

Downloads

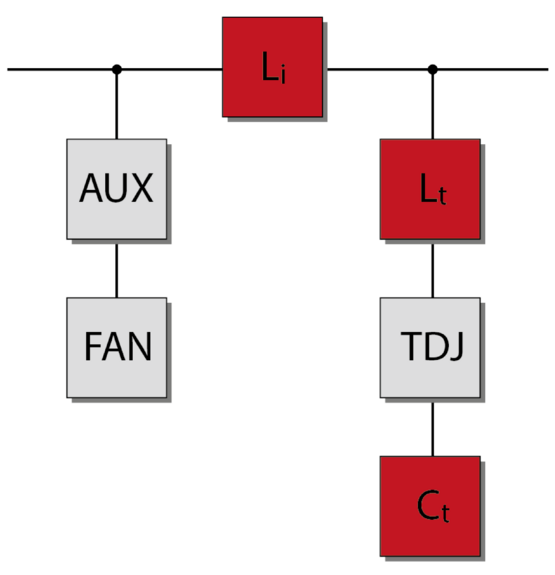

Ecosine Flex, 200-480 VAC 60 Hz 10% THDi Passive Harmonic Filters

- Reduce THDi to 10% (15% if no DC-Link present in the drive)

- Filters for diode rectifier with and without DC-link choke and thyristor rectifier

- Help to comply with EN 61000-3-12, IEEE 519 and other PQ standards

- Increase the efficiency of energy utilization

- Most compact design

- Plug and play, ready to use

Features and Benefits

FN3458 (60 Hz) models of the Ecosine Flex product family represent the very compact economical series with a THDi performance of <10% for drives with 4% Ldc and <15% for drives without Ldc.

They are ideal for non-linear three-phase equipment with B6 rectifier front-end that do not require the industry leading <5% THDi performance provided by Schaffner Ecosine Evo filters.

The performance targets the requirement of EN 61000-3-12 and IEEE 519 for Isc/IL <50. Schaffner Ecosine filters help to unburden the electrical infrastructure from excess loading and heat caused by current harmonics, and therefore support a better utilization of electric system capacity.

Lower harmonics also reduce the risk of system resonances and potential downtime of sensitive electronic equipment.

FN3458 filters upgrade standard motor drives to low-harmonic drives quickly and easily.

Typical Applications

Technical Specifications

Nominal operating voltage

3x288 to 480 VAC ±10% for IP00

3x380 to 480 VAC ±10% for IP20

Overload capability

1.6x rated current for 1 minute, once per hour

Operating frequency

60 Hz ±1 Hz

Total harmonic current distortion THDi*

<10% @ rated power (with DC-Link choke 4%)

<15% @ rated power (without DC-Link choke or <4%)

Total demand distortion TDD

According to IEEE 519

Nominal motor drive input power rating

5 to 250 HP @ 480 VAC

High potential test voltage

P -> E 2480 VAC for 1 s

Earthing system

TN, TT, IT

Efficiency

≥ 98% at rated voltage and power

Overvoltage category

OV III (IEC 60664-1 / UL 61800-5-1)

Temperature range (operation and storage)

–25°C to +45°C fully operational

+45°C to +70°C derated operation***

–25°C to +85°C transport and storage

Cooling

Internal fan cooling or external fan cooling****

Protection category

IP 00, IP 20

Flammability corresponding to

UL 94V-2

Design corresponding to

UL/IEC 61800-5-1, EN 61800-5-1, CE (LVD2006/95/EC)

Choke: IEC 61558-2-20

SCCR**

100 kA

MTBF (Mil-HB-217F)

>300,000 h @ 45°C/480 V